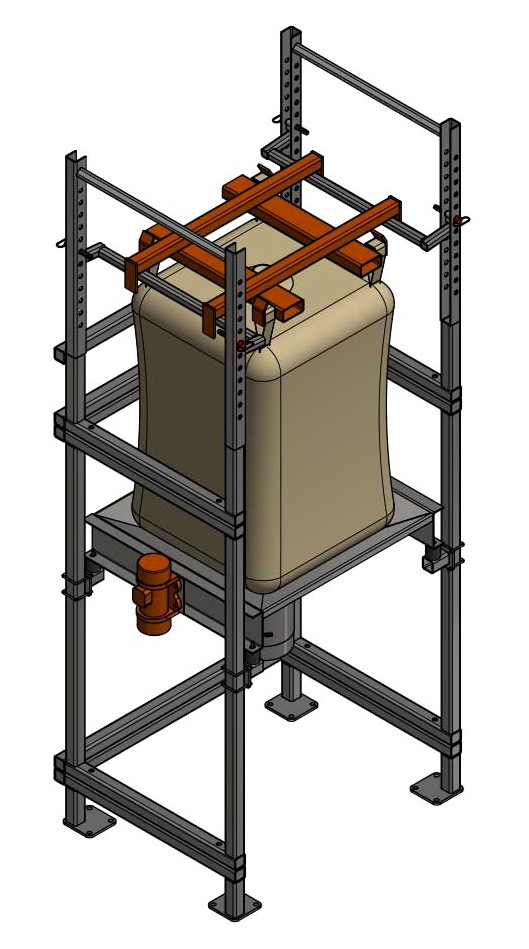

Bulk Bag Unloader (forklift style)

Model 4100

Model 4100 Heavy-Duty Bulk Bag Unloaders are designed

to be forklift loaded. They can discharge and condition materials packaged in 1,000 to 4,400 pound bulk bags. Ideal 4100 applications are free flowing powders, granular, or pelleted materials to be distributed into downstream processes or filling equipment.

Click Image for Larger View

Operation:

Lower the hoist mounted bag lift rack over a bulk bag setting at floor-level. Secure the bag lift straps. Using the pendant controls, lift the bag up onto the unloader support structure. From the operators platform, the operator will untie the bags discharge spout, inside the untie box, and allow product to flow out.

Technical Specifications:

Proper application free flowing and semi-free flowing powders

Weight range 550-3,000 pounds (250-1,350KG) bulk bags (super sacks)

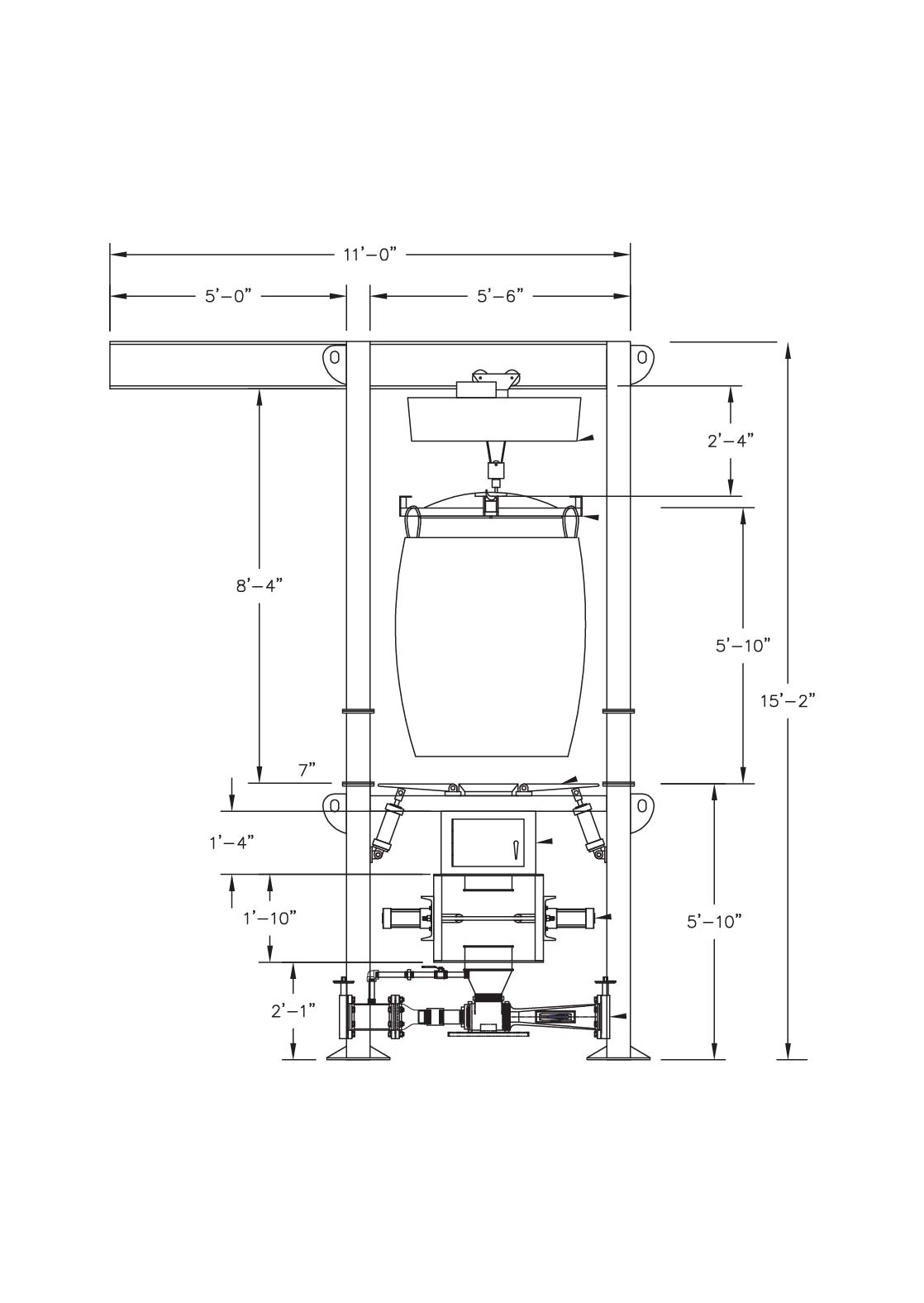

Dimensions- 180” tall x 68” deep (60” between legs)

Designed to handle bag sizes up to 48”(122cm) long x 48” (122cm) wide x 54” 137cm) tall (maximum size not including bag straps assuming 10” (25cm) long bag strap loops)

Control air 80 PSI required @ 1 CFM per bag fill cycle (base unit requires no compressed air)

Electrical – 115 volt, 1 phase, 60 cycle (hoist -220/440 volt/ 3 phase, 60 cycle) (base unit requires no electrical power)

Dust collection pickup minimum 400 CFM (base unit not supplied with dust collection take-off connection)

1 year limited warranty

STANDARD FEATURES:

Carbon steel material contacting surfaces

4”x4: square tubing support structure ( ¼” wall)

Powder coated CBE almond

Vertical lift adjustment for different bag sizes

2 section assembly with flanged connections for easy assembly support rail with end strops for 2 ton hoise assembly (hoist sold separately)

STANDARD OPTIONS:

401-100 Bag massaging agitator paddles (M/S)

402-100 Dust tight bag untie box (M/S contact)

402-300 Dust tight bag untie box with integrated pinch valve (M/S contact)

404-100 Air operated multi-position slide gate material flow cutoff valve M/S contact)

405-200 15” Iris valve (304 S/S contact)

406-400 Vibratory bin bottom bag fluidization system (304 S/S)

407-200 2 Ton Cap. Pneumatically powered hoist and trolley (15’ lift, 8 FPM)

401-200 Bag massaging agitator paddles (304 S/S)

402-200 Dust tight bag untie box (304 S/S contact)

402-400 Dust tight bag untie box with integrated pinch valve (304 S/S contact)

405-100 15” Iris valve (aluminum contact)

406-100 Vibratory bin bottom bag fluidization systems (M/S)

407-100 2 Ton cap. Electrically powdered hoist and trolley (15’ lift, 8 FPM)

419-100 Anti-corrosive package for 400 series bulk bag fillers

CHOICE BAGGING EQUIPMENT

4804 N Main St,

Taylor, TX 76574

Hours

Monday-Friday 8am-5pm

Saturday & Sunday: Closed