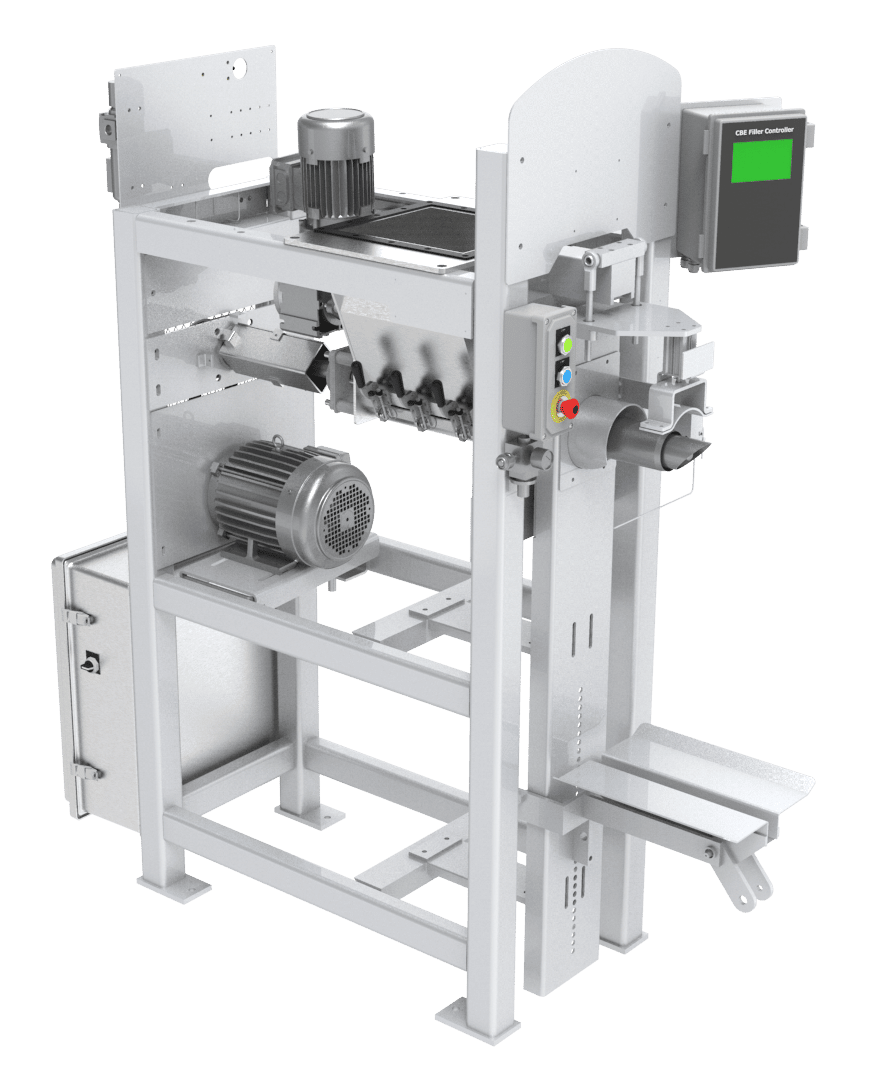

Clean-Duty Auger Valve Bag Filler – Model 2050

Key Features & Benefits

Air-operated clamp hold bags securely for no mess filling

Can be configured for wash down to make cleaning easy

Touch screen with straightforward controls simplifies operator training

Compact size operates in as little as 72” (183cm) of vertical space

Fills bags using limited aeration for packaging and transportation savings

Handles a wide variety of materials and bag types, built to be mobile

Heavy-duty auger feeder with low maintenance shaft seals reliably fills bags

Standard Equipment:

304 stainless steel product contacting surfaces w/ 2B sanitary interior finish

Continuously welded, polished and radiused interior corners

All interior facing unwelded joints can be disassembled for cleaning

No nuts, bolts, or other fasteners

“Quick change” continuously welded, polished auger decouples in less than two minutes

Solid shaft spike agitator with removable tines, machined wrench flats for easy disassembly

Hinged drop bottom cleanout with Des-Ta-Co quick release clamps (includes safety switch)

Split gland rope packing shaft seals with USDA Teflon

Digital load cell weighing scale with easy-to-use touch screen controls

Variable bulk and dribble auger filling speeds

Single wall, fill spout (sized per customer requirement)

High gloss white epoxy powder coating

NEMA 4X polycarbonate electrical enclosures

Optional Equipment:

Steel-it paint and stainless-steel fasteners

Stainless-steel construction

NEMA 4X stainless steel electrical enclosures

Scale with integrated vibratory bag settler

Variable speed motor drive

Inflatable dust seal for filling spout

Tapered dust seal cone

Inflatable dust seal for filling spout

Casters for ease of mobility

CHOICE BAGGING EQUIPMENT

4804 N Main St,

Taylor, TX 76574

Hours

Monday-Friday 8am-5pm

Saturday & Sunday: Closed