OPEN MOUTH BAG Filler MACHINES

Open mouth bag fillers are versatile machines designed to weigh, fill, and seal a range of materials in various bag types. They can package free-flowing and granulated products as well as substances that move with difficulty. That’s why open mouth bag fillers are used for so many different applications. This includes everything from seeds to feed, flour to sugar, sand to gravel, and plastics to industrial chemicals. Finally, open mouth bag fillers can operate manually or in semi or fully automatic mode depending on the need.

Open Mouth Bag Fillers

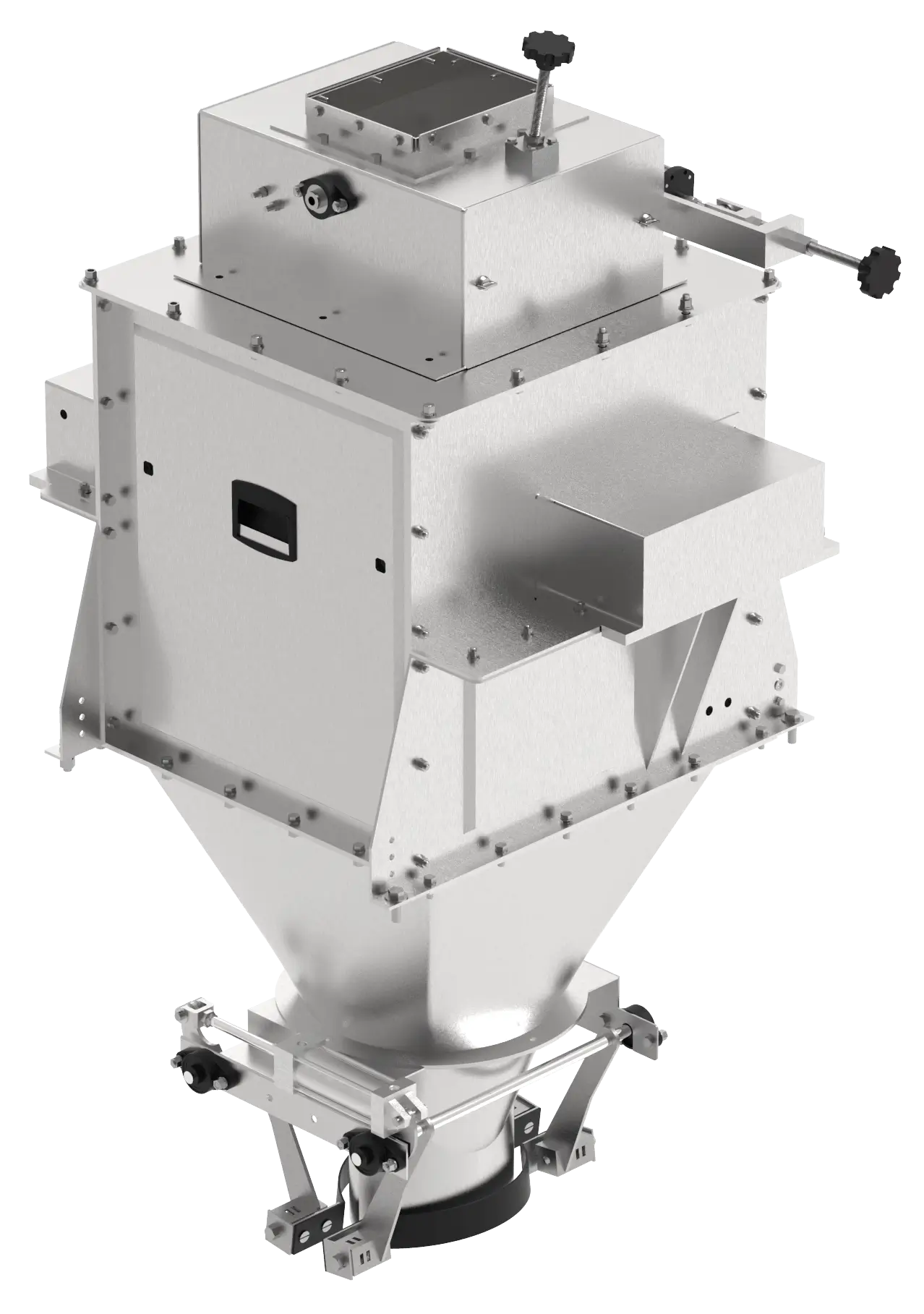

The Gravity Open Mouth Bag Filler is designed to bag many kinds of free-flowing pellets and granules. It is a simple, economical filling machine for low production needs which requires no utilities.

Examples of materials this machine bags: deer corn, hard grains & seeds, fertilizer, plastic pellets, sand (dry), and pea gravel.

Fills up to 6 bags per minute.

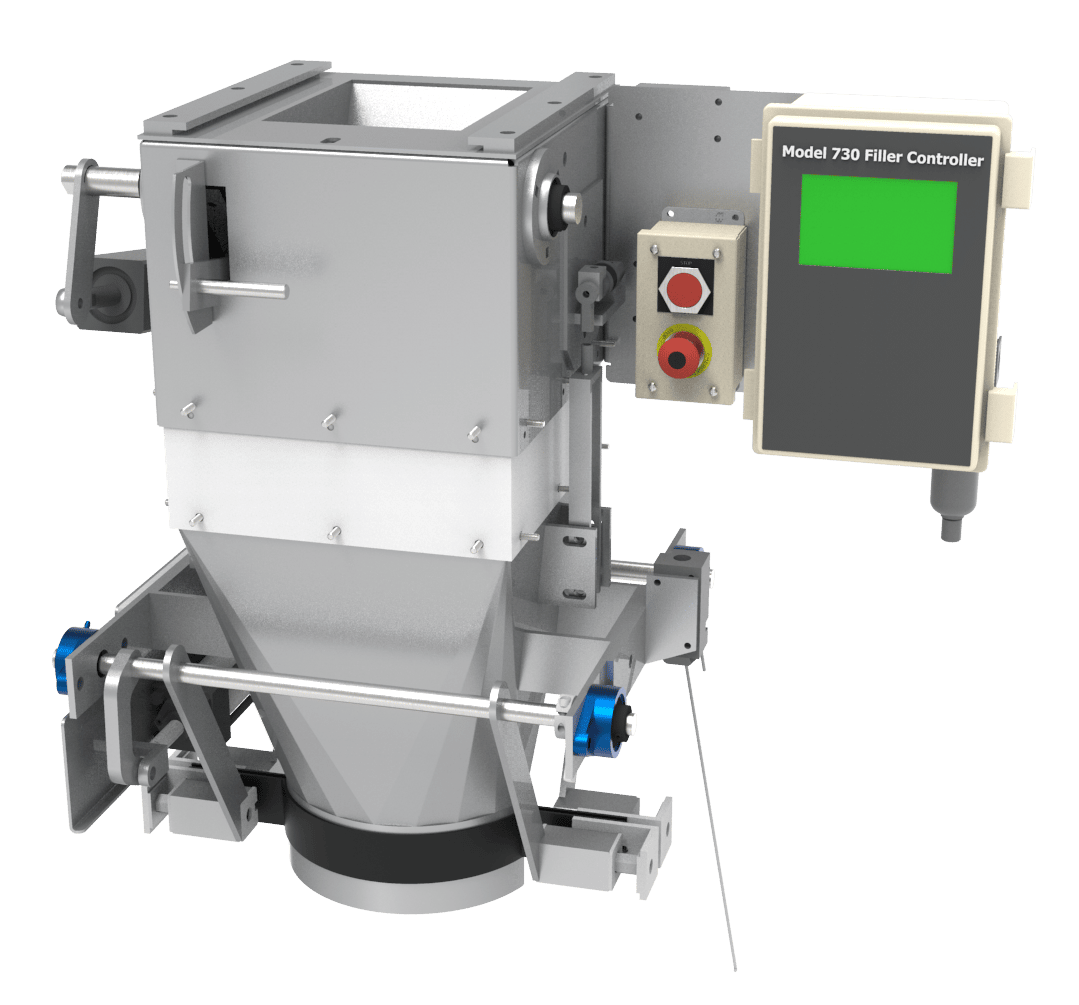

A true workhorse, the Digital Gravity Open Mouth Bag Filler can package many types of free-flowing pellets and granules. It’s a very dependable gravity filling machine built for clean, accurate bagging.

Examples of materials this machine bags: deer corn, hard grains & seeds, pelleted feeds, fertilizer, corn meal, plastic pellets, sand (dry), and pea gravel.

Fills up to 6 bags per minute.

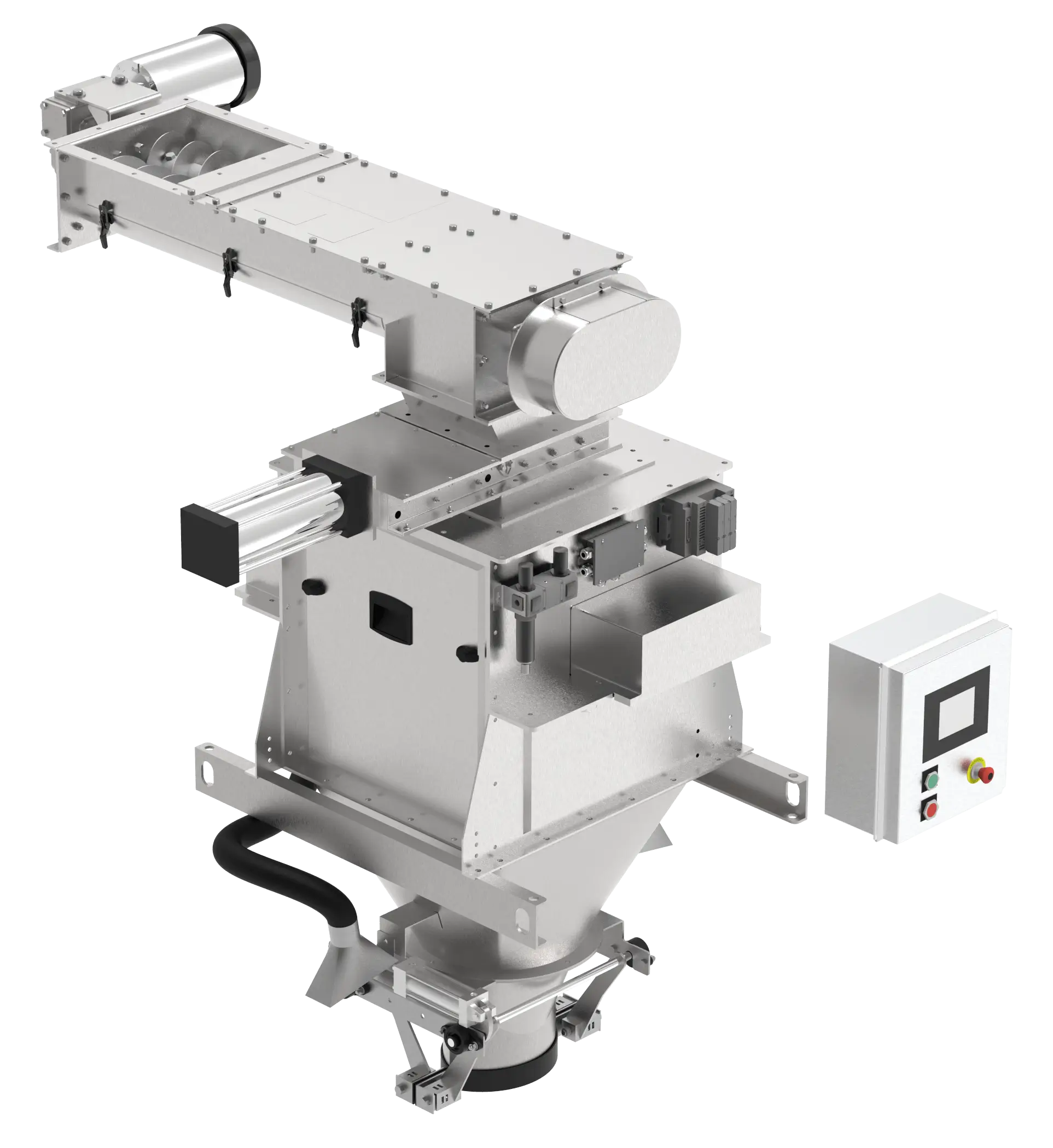

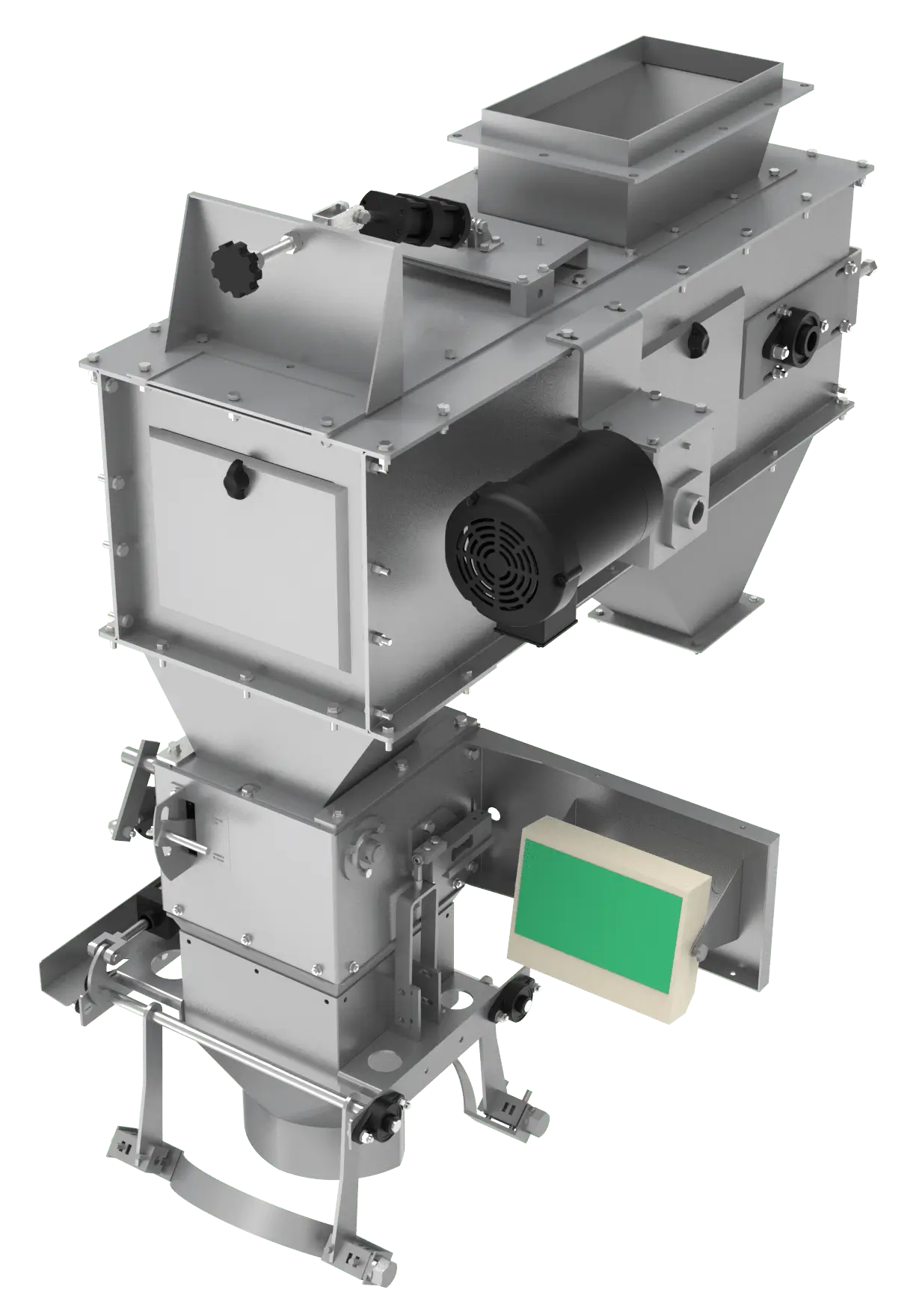

Our Twin Auger Open Mouth Bag Filler works with many types of free and semi-free-flowing powders. Its twin auger feeders control material flow for precise bag weights.

Examples of materials this machine bags: mineral powders, cement powders, plaster, pigments, graphite, flour, bakery mixes, cocoa, spices, pepper, animal grade pharmaceuticals, and nutraceuticals.

Fills up to 6 bags per minute.

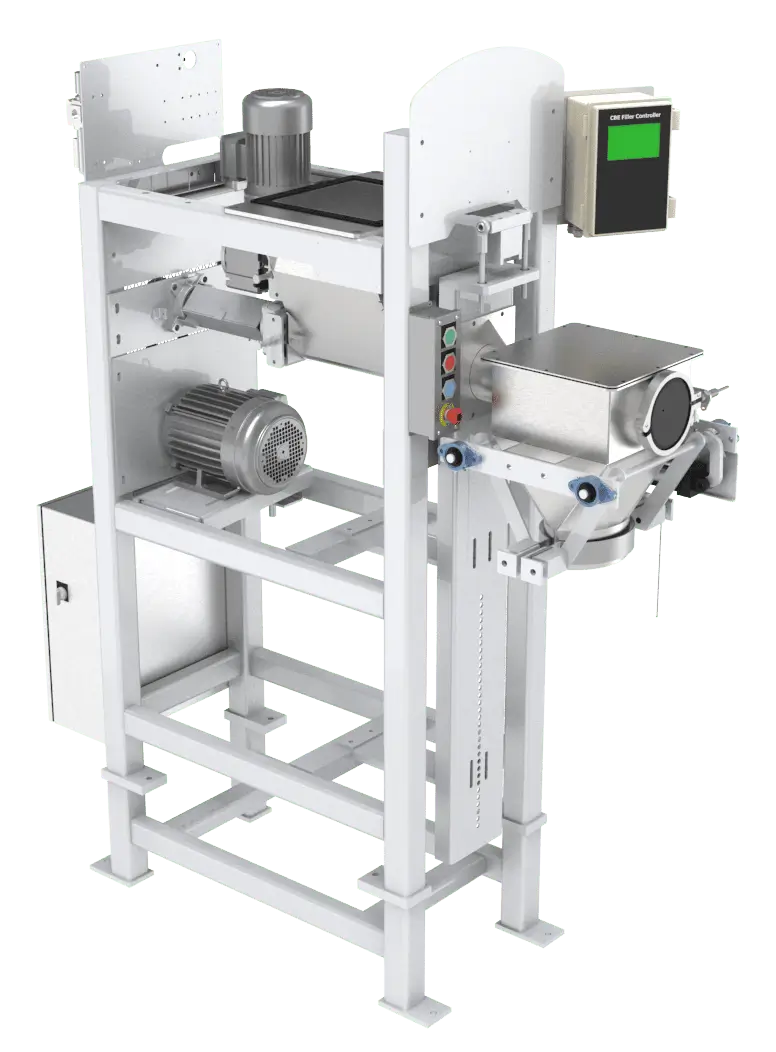

Packs many types of finely ground industrial grade powders in open mouth bags. Dependable in harsh, demanding environments.

Examples of materials this machine bags: mineral powders, cement powders, plaster, pigments, graphite

Fills up to 4 bags per minute.

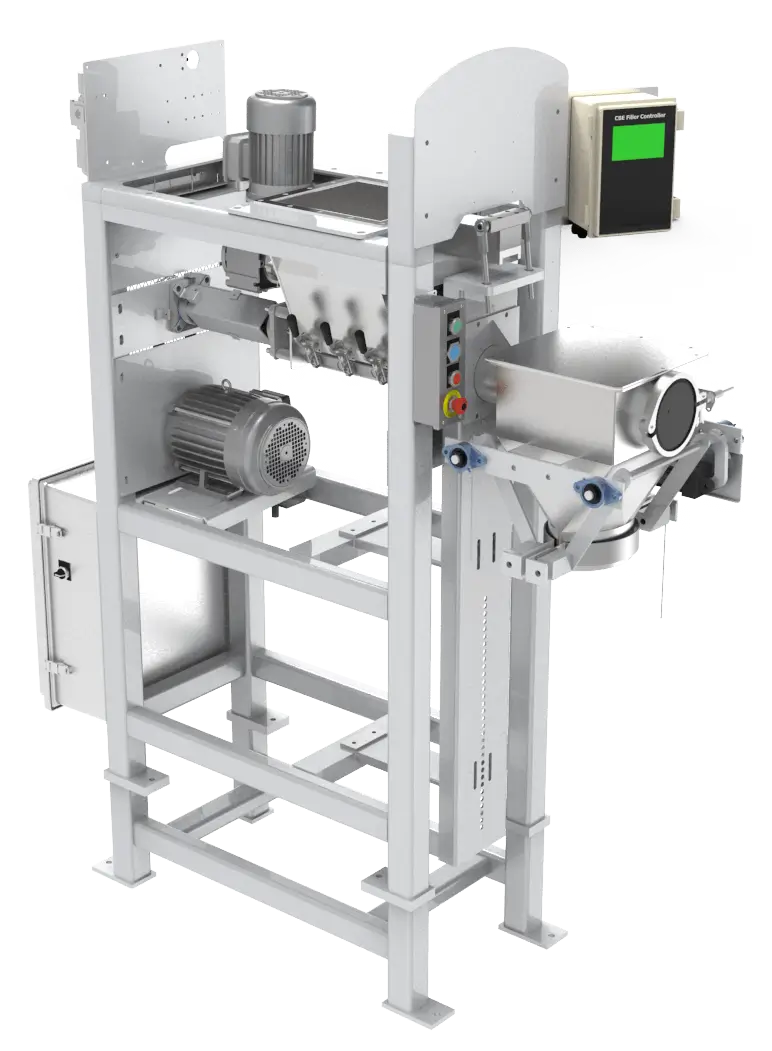

Bags a variety of finely ground sanitary grade powders. Ideal for applications requiring cleaning between uses.

Examples of materials this machine bags: flour, bakery mixes, cocoa, spices, pepper, animal grade pharmaceuticals, nutraceuticals.

Fills up to 4 bags per minute.

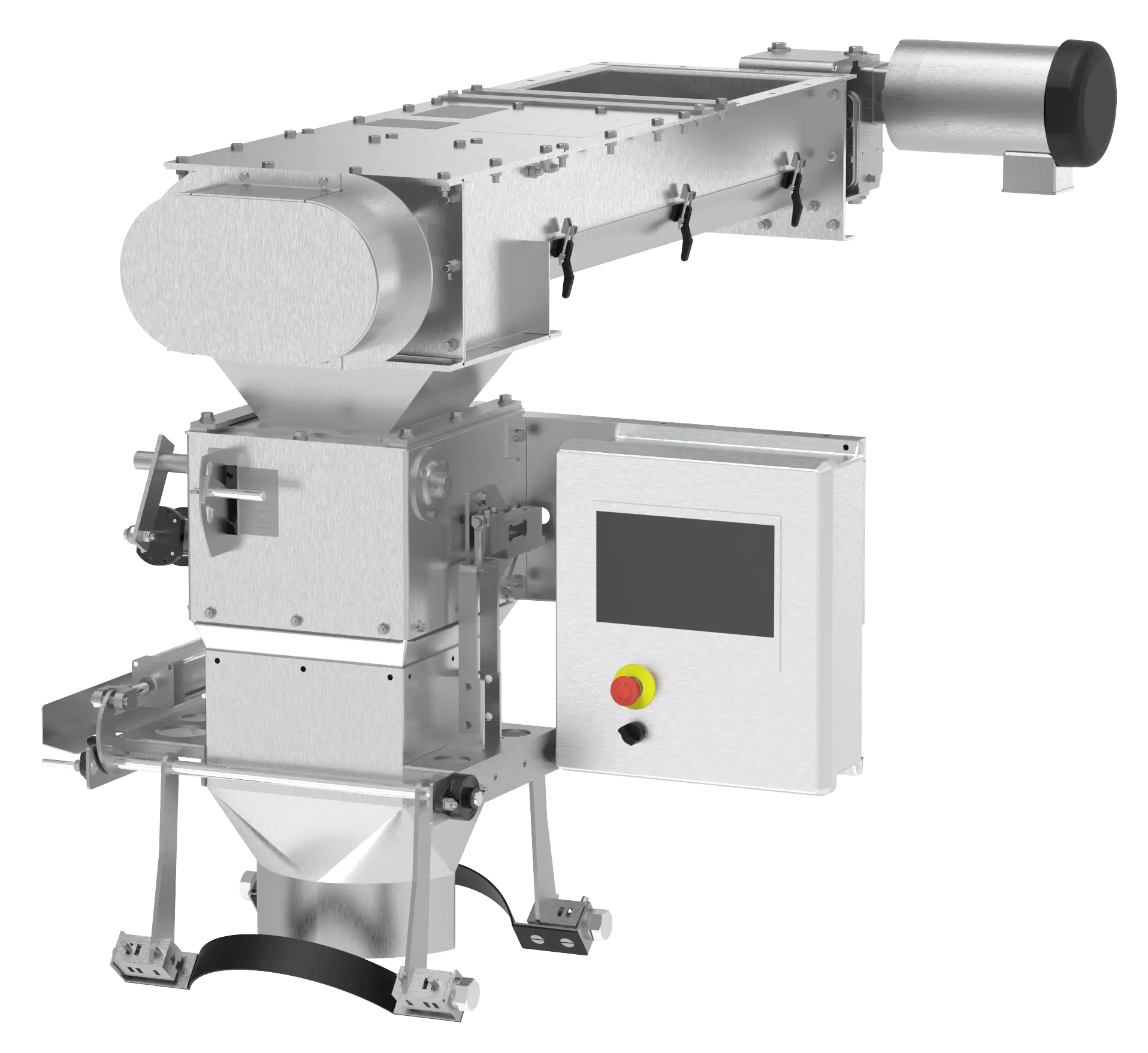

This gravity filling machine bags free-flowing granulated and pelleted materials at high speeds. It provides dependable, accurate, dust-free filling.

Examples of materials this machine bags: deer corn, hard grains & seeds, pelleted feeds, fertilizer, plastic pellets, sand (dry), pea gravel.

Fills up to 24 bags per minute.

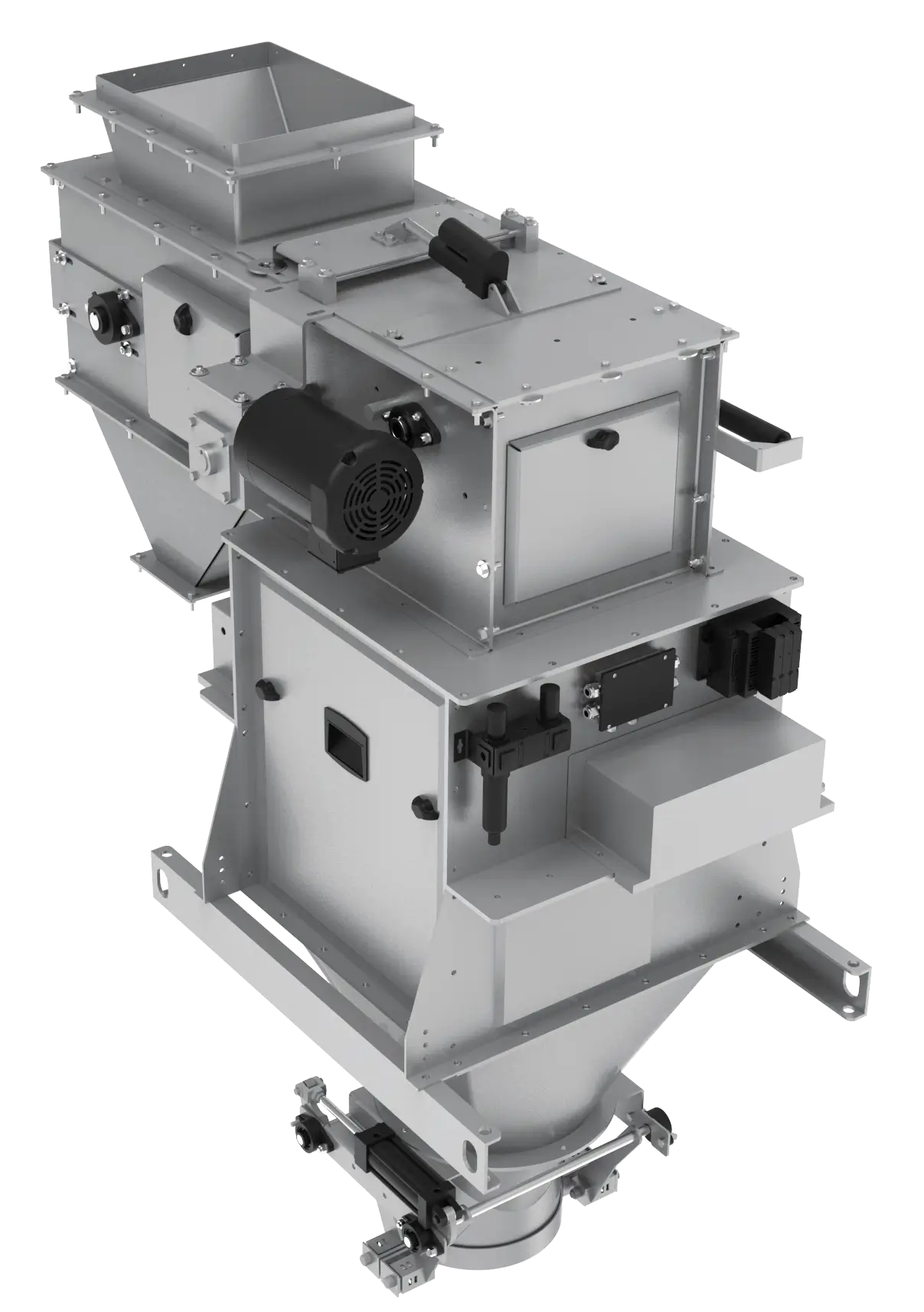

Fills bags with a broad range of finely ground industrial grade powders. A dependable workhorse for harsh and demanding operating environments.

Examples of materials this machine bags: mineral powders, cement powders, plaster, pigments, graphite, flour, bakery mixes, cocoa, spices, pepper, animal grade pharmaceuticals, nutraceuticals.

Fills up to 8 (single scale) or 16 (double scale) bags per minute.

Open Mouth Bag Fillers For Special Applications

Engineered for rapid bagging of sticky, large particle materials that may flow with difficulty. A belt helps prevent binding or compacting.

Examples of materials this machine bags: oat flour, cattle cubes, molasses feed, brown sugar, bone meal, fish meal.

Fills up to 24 bags per minute.

Designed for high density, free-flowing, granulated, low-dust materials. Bags with precise weight measurements.

Examples of materials this machine bags: ice melt, sand, sugar, carbide (dry), pea gravel.

Fills up to 6 bags per minute.

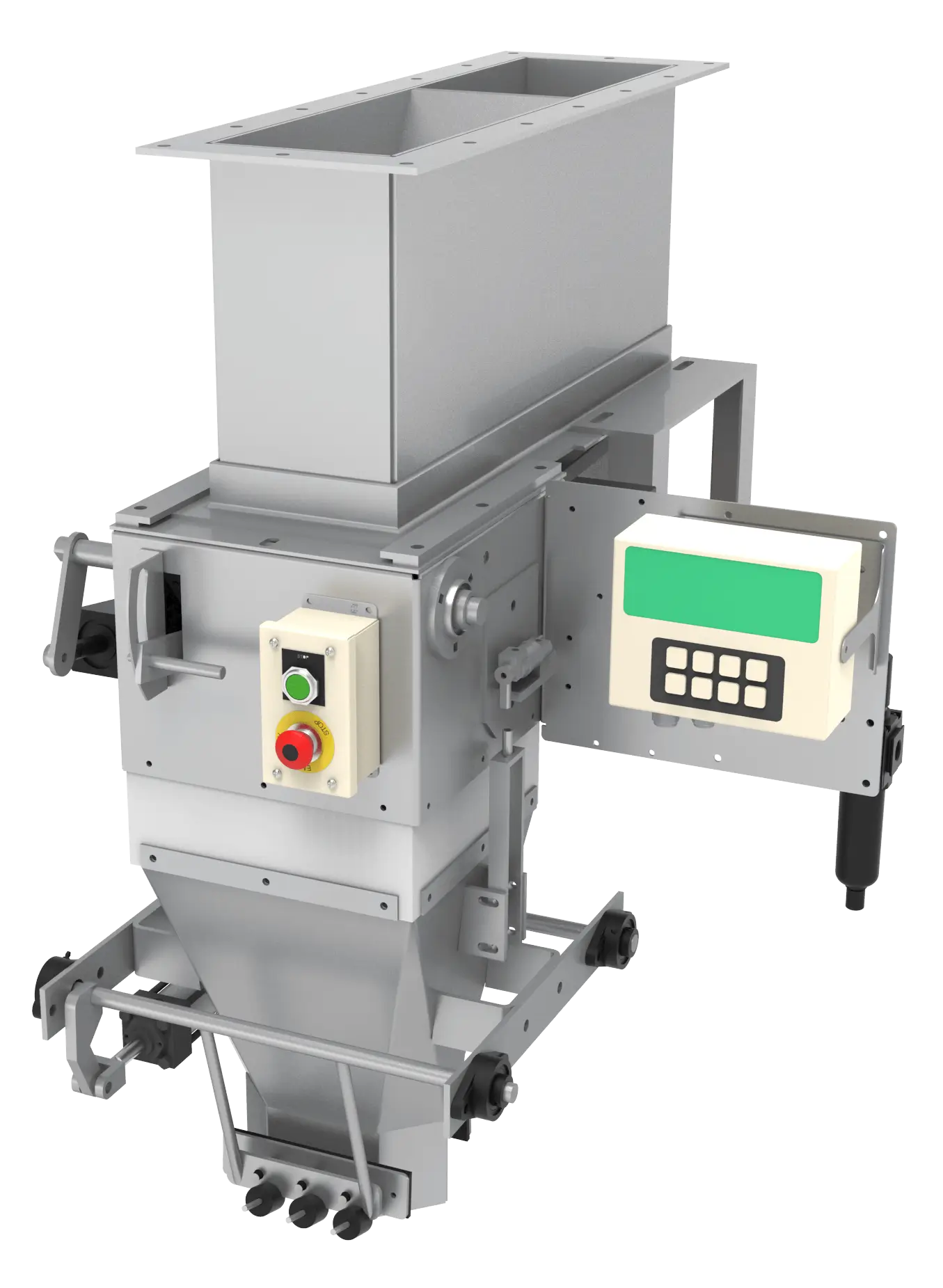

Made for difficult to flow, large particle, sticky materials. Best for uses where materials bind or compact when accumulated en masse.

Examples of materials this machine bags: brown sugar, molasses feed, cattle cubes, oat flour, fish meal, bone meal.

Fills up to 6 bags per minute.

What are the Basics of Open Mouth Bagging Machines?

Well suited for manual or automated operation, open mouth bagging machines quickly package food and non-food grade materials. They’re also ideal for dry, free-flowing, and hard-to-handle substances with minimal dust. Lastly, they work well with landscaping, feed, seed, nuts, and fertilizer products.

What are Their Classes & Feeder Systems?

Open mouth bag fillers are organized in two classes. The first is gross weigh machines that fill and weigh bags simultaneously. Next is net weigh baggers that pre-weigh and fill as a secondary step. Each bag filler class can be fed by one of the following systems: gravity, vibratory pan, belt or auger.

What is an Open Mouth Bag?

Open mouth bags come in a variety of types based on specific manufacturer needs. They include pinch bottom (paper), sewn open mouth (both paper and plastic), and heat sealed (film) bags. Depending on their construction, open mouth bags are usually closed by sewing, heat sealing, or gluing.

Sewn open mouth bags are the preferred choice for agriculture, feed, and seed applications. Economical and tough, they’re easily opened with a pull tab cord at the top. This bag style can also be manufactured with PE-free film or PE-liners for enhanced moisture protection.

What are Typical Open Mouth Bag Filler Applications?

Building Materials

Fertilizer, Plastic Pellets

Food Products

Sugar, Salt, Cake Mixes, Flour, Spices, Cocoa

Agricultural Products

Animal Feed, Seed, Corn, Soybeans

Landscaping Products

Soil, Compost, Sand, Gravel

Advanced Systems with Open Mouth Bagging Machines

Open mouth bagging machine systems are available for high-volume production. They can be configured with multiple bagging stations matched with robotic bag placers and automated bag palletizing robots. When fully implemented, these systems package and stack up to 1,440 bags per hour, per line. Further automation can also be applied with bag flattening conveyors, robotic bag turners, and pallet wrappers. Ultimately, bagging machine systems like this enable one operator to manage everything and output thousands of bags hourly.

Let Choice Bagging Help Find Your Perfect Open Mouth Bag Fillers

Choosing the proper open mouth bag fillers can be difficult because of the many different factors to be considered. This includes type of bags you’re using, the speed at which you need them sealed, and your budget. All of these and more will influence your decision. Why not contact us today and let Choice Bagging Equipment simplify the process for you?

CHOICE BAGGING EQUIPMENT

4804 N Main St,

Taylor, TX 76574

Hours

Monday-Friday 8am-5pm

Saturday & Sunday: Closed