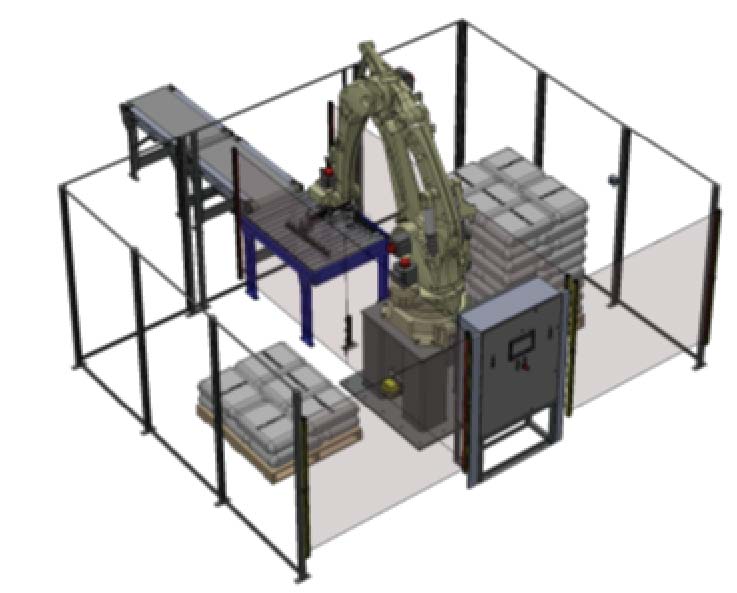

Model 3100 “Hot Swap” Robotic Palletizer

Our Model 3100 Hot Swap Robotic Palletizer is actually a set of machines and equipment that work together. It is typically used for applications that require stacking 1 to 12 bags per minute. The system operates by automatically accumulating and indexing bags to a pick station and then placing them on pallets. Model 3100 has two workstations where bags are stacked layer by layer in a pre-programmed pattern until completion. Once a pallet is full, the 3100’s robotic palletizer arm pivots to the other work cell. An operator can then safely enter the first cell, remove the loaded pallet, and drop an empty one to start again.

Rear view

Click to View Video

Robotic Palletizer with Deer Corn

Model 3100 Robotic Palletizer

Key Features & Benefits

Automatically places paper, poly film, and woven bags on pallets

Capable of stacking both 2-way and 4-way pallets

Includes an HMI (human machine interface) display with straightforward controls to simplify operator training

Compact footprint can be as small as 18’ x 18’ square (three layout configurations available)

Handles a wide variety of materials (powders, flakes, granules)

Specifications

Bag palletizing weight range: 20-110 lbs. (9-50 kg)

Production rate: 1-12 bags per minute (material and bag size dependent)

Bag lengths: 19" minimum, 26" maximum

Operating mode: automatic bag stacking with manual empty and filled pallet exchange

Overview

Kawasaki CP-180 robot capable of palletizing up to 50 KG bags at a maximum rate of 12 per minute with a 2.5x safety factor

Elevated robot riser constructed of structural plate and channel

Claw style bag gripper with pneumatically operated controls

Live roller bag pickup conveyor

Dual zone bag index conveyors designed to control the advance of filled bags to the robot

Pallet locating guides to aid operators in consistent pallet placement

Fully integrated safety fencing with (4) sets of light curtains guarding operator access; also includes muting ability for pallet exit from the cell

Machine tagging optimized for rapid technical support

CHOICE BAGGING EQUIPMENT

4804 N Main St,

Taylor, TX 76574

Hours

Monday-Friday 8am-5pm

Saturday & Sunday: Closed