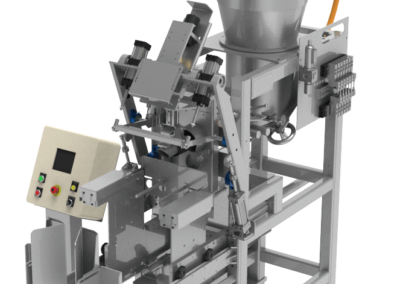

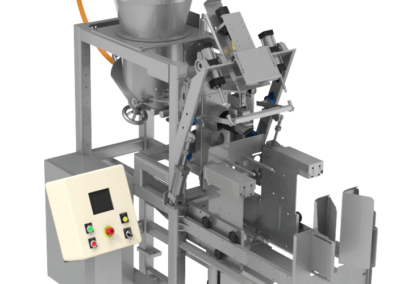

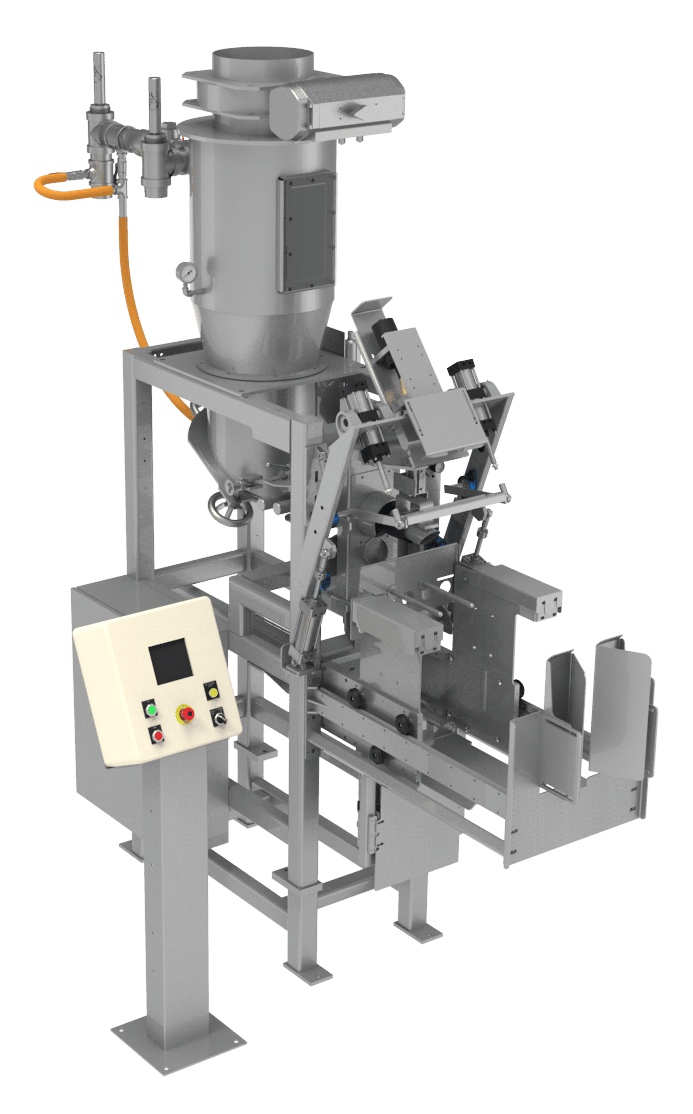

Sonic Seal Forced Air Valve Bag Filler

Model 7550

The Sonic Seal Forced Air Valve Bag Filler pressurizes and fluidizes substances to flow smoothly into bags. After loading, ultrasonic technology swiftly closes the bags and discharges them bottom end first. Model 7700 is constructed of continuously welded thick wall box steel tubing for rugged and continual use with little maintenance. It can bag a wide range of materials and allows rapid cleaning and inspection of interior contact areas.

Click to View Videos

Model 7550 with Robotic Bag Placer Bagging, Sealing, & Discharging Sodium Bicarbonate Peroxyhydrate

Model 7550 with Robotic Bag Placer Bagging, Sealing, & Discharging Oat Flour

Model 7550 with Robotic Bag Placer Bagging, Sealing, & Discharging Carbon Black

Examples of Materials Bagged with this Machine

Starch, corn flour, oat flour, powdered sugar, calcium carbonate, pelleted carbon black, activated carbon, copper sulphate, pigments, plastic pellets, resins and chemicals powders

Powders with fine granules

Specifications:

Bag filling weight range: 20-66 lbs. (9-30 kg)

Production rate: 1-3 bags per minute (material and bag size dependent)

Material density range: 30-75 lbs. (13.63-36.36 kg) per cubic foot

Operating modes: Semi- (operator assisted) or fully automatic

Bag types: Internal sleeve and/or tuck-in sleeve perforated paper, plastic film, and poly woven bags

CHOICE BAGGING EQUIPMENT

4804 N Main St,

Taylor, TX 76574

Hours

Monday-Friday 8am-5pm

Saturday & Sunday: Closed