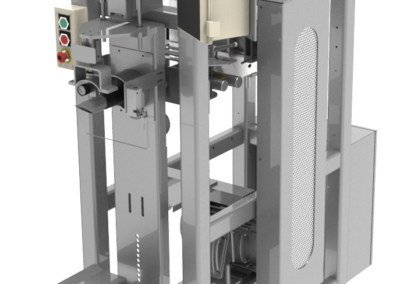

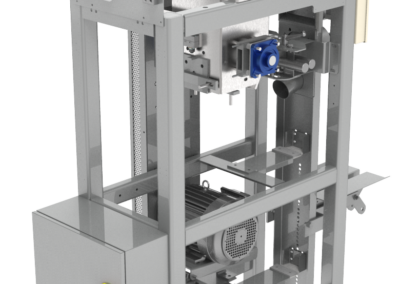

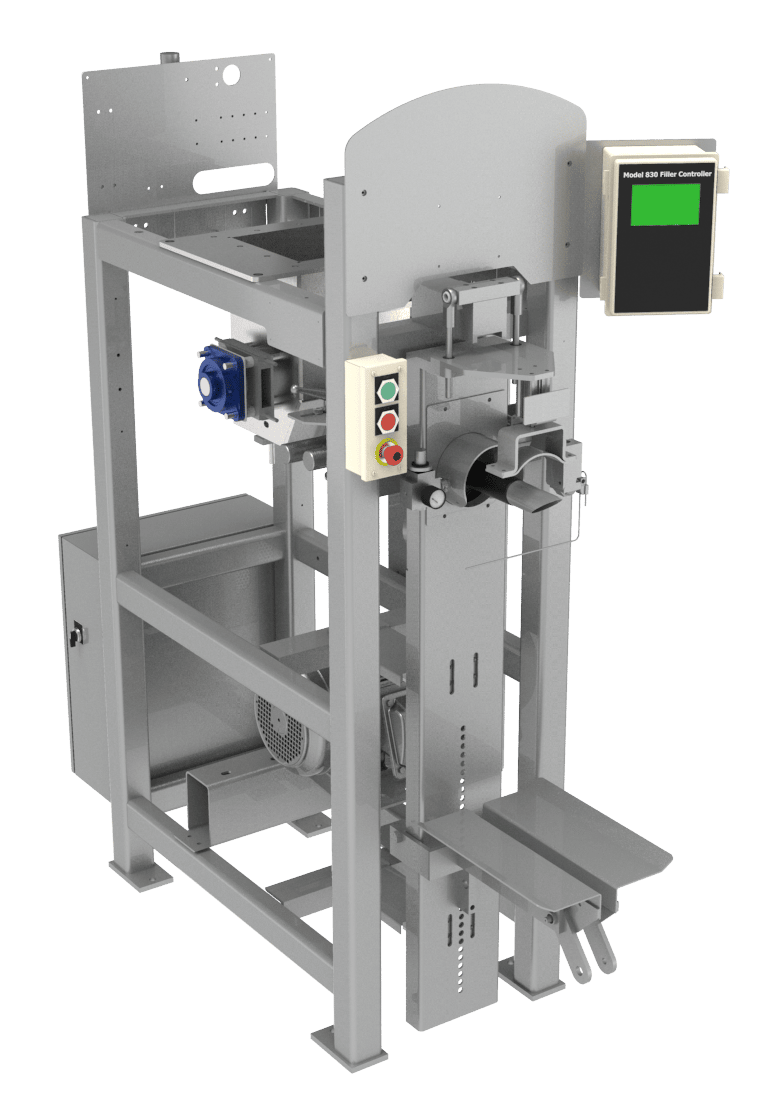

Digital Vertical Impeller Valve Bag Filler

Model 8300

Model 8300 is a valve bag filler designed for very fine powders with fluid-like flow properties. It has a specialized rotary vane feeder which moves materials at high speeds as if they were liquids. Twin feeding screws ensure an accurate and consistent flow through the turbine and into bags. The machine is constructed of continuously welded thick wall box steel tubing for rugged and continual use with little maintenance. It can bag a wide range of materials and is set up for rapid cleaning and inspection of interior contact areas.

Click to View Videos

Model 8300 Bagging Mortar

Model 8300 with Bag Auto Discharge; Flattening & Hip Palletizing Conveyors

Model 8300 Precision Cement Packaging with Auto Bag Discharge

Examples of Materials Bagged with this Machine

Portland cement, masonry cement, flyash, calcium carbonate, plaster, mortars, bentonite, gypsum

Powders

Specifications:

Bag filling weight range: 20-110 lbs. (9-50 kg)

Production rate: 1-8 bags per minute (material and bag size dependent)

Material density range: 50-100 lbs. (22.7-45.45 kg) per cubic foot

Fill rate: 1-12 bags per minute (depending on product characteristics and bag sizing)

Operating modes: Semi- (operator assisted) or fully automatic

CHOICE BAGGING EQUIPMENT

4804 N Main St,

Taylor, TX 76574

Hours

Monday-Friday 8am-5pm

Saturday & Sunday: Closed