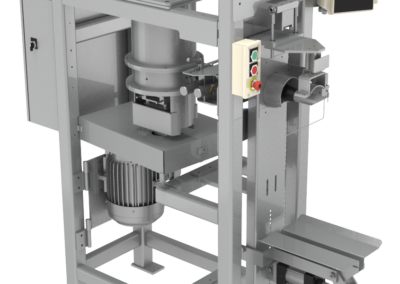

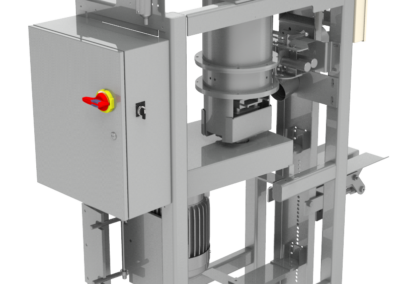

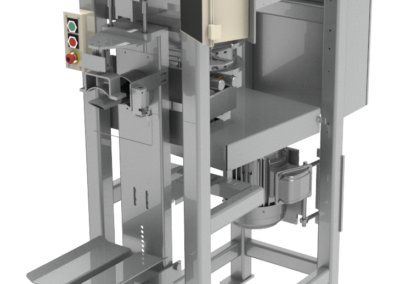

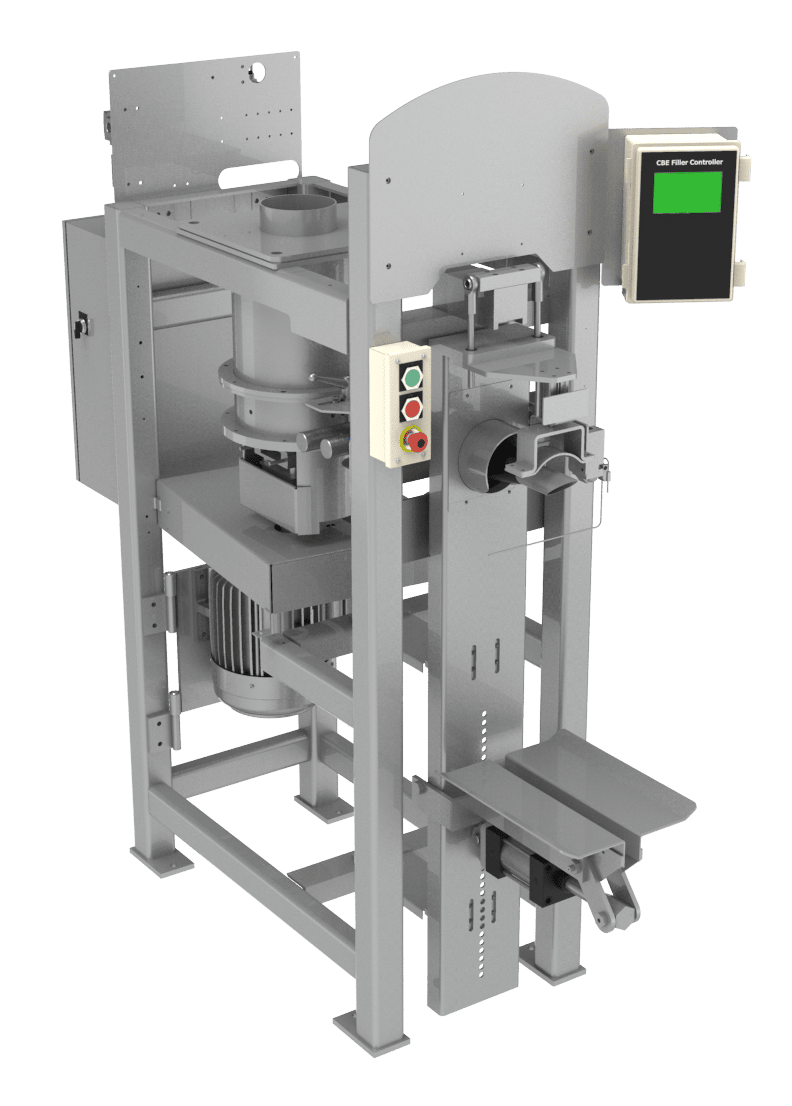

Digital Horizontal Impeller Valve Bag Filler

Model 9300

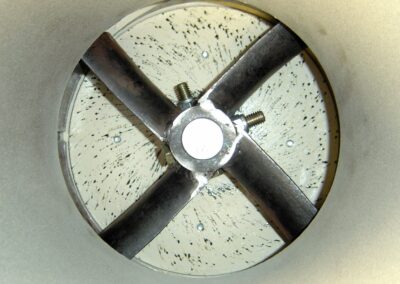

Model 9300 is designed to bag many types of light bulk density powders possessing fluid-like flow properties. It has a specialized horizontal rotary vane feeder (impeller) which conveys material without causing aeration as it passes through the machine during the filling process. The design features a vertically rotating shaft with horizontally rotating blades that create a positive draw on material as it feeds into and through the machine.

Click to View Videos

Model 9300 Bagging Cocoa Powder w Integrated Sealer & Turn/Flatten Conveyors

Model 9300 Silica Powder Bagging Test

Model 9300 w Integrated Sealer Bagging Silica Powder

Examples of Materials Bagged with this Machine

Talc, kaolin clay, hydrated lime, hydrated alumina, graphite, carbon black, activated carbon, silica fume, rice hull ash

Powders mixed with course granules

Minerals

Flakes

Specifications:

Bag filling weight range: 20-110 lbs. (9-50 kg)

Production rate: 1-8 bags per minute (material and bag size dependent)

Bag types: Internal sleeve and/or tuck-in sleeve perforated paper, plastic film, and poly woven bags

Material density range: 15-60 lbs. (6.8-27.3 kg) per cubic foot

Operating modes: Semi- (operator assisted) and fully automatic

CHOICE BAGGING EQUIPMENT

4804 N Main St,

Taylor, TX 76574

Hours

Monday-Friday 8am-5pm

Saturday & Sunday: Closed